No, not casting cuttlefish but using their unique internal shell, the cuttlebone, to make small casts.

Thousands of years ago, someone worked out that the cuttlebone is easy to carve and will take fine lines, it’s slow to transmit heat and is cheap – if you live near the sea. We know because very old jewellery has the characteristic wavy pattern generated by the fine structure of the cuttlebone.

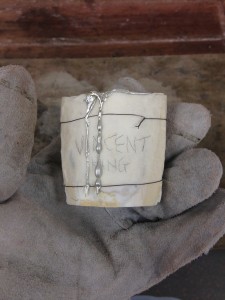

There’s a bit of getting abutting surfaces flat, making sure that the carved portions line up and there are some “runners” and “risers”, which help the metal flow. Here’s one poured before opening and ‘open’, you can see the grooves for those “runners” and “risers”.

There is only a little bit of fishy smell as we cast pewter but I’m told that hotter metals cause more of a stink. Generally, they are “one off” copies. Being marine and a cephalopod, I decided to cast a fish as the first ‘carve only one side’ piece, and a sort of nautilus as the third piece [the red is fine casting sand to stop leaks of metal – it all drained out on first pour!]. You can clearly see the wavy pattern of the cuttlebone in the cast on the left and it gives the texture in the right photo [sorry for quality].

The ring was a have a go, experiment with shape – don’t think I’ll get anyone to wear it [but I am definitely going to use the technique again!].

Next, I think it might be working copper or wood……